As summer moves into fall, logistics professionals face a new set of regulatory challenges to reckon with. Among them, a federal English proficiency ruling that came into effect on June 25, mandating that all truck drivers must be able to understand and speak English in order to operate on US roads. With an ongoing labor shortage showing no signs of abating, the implications for freight firms will be seismic.

This isn’t lost on fleet managers. During our latest round of research, 10% of respondents indicated that “adapting to regulations” was a key focus for them in July 2025 – up from just 4% in June. It’s a massive spike that points to both fleet owners’ shifting priorities and the looming specter of regulatory hurdles.

With this in mind, I’ve put together an action plan to help your fleet get ready for future compliance challenges, so you won’t be caught cold and forced to scramble when the unexpected comes into force.

What’s Happened? The English Proficiency Requirements

In April 2025, President Trump issued a new executive order to “keep American families safe on the road.” As part of the ruling, Transportation Secretary Sean Duffy was instructed to “rescind guidance that watered down the law requiring English proficiency for commercial drivers.”

The Transportation Secretary signed the new guidance into law a month later. Following a Commercial Vehicle Safety Alliance (CVSA) vote to uphold the law, it officially came into effect on June 25: this meant a ban on non-English speaking truck drivers on US roads.

With an estimated three million non-English speaking drivers in the US, the impact will be enormous. But it gets worse — the logistics industry is currently facing a crippling labor shortage and, if nothing changes, there will be 160,000 fewer drivers than needed by 2030.

While our original research shows that recruitment and retention has actually fallen in priority for the second consecutive month, it’s still top of mind for many across the industry.

What’s Next? Forecasting Upcoming Regulatory Challenges

In this section, I’ll take you through some of the rumored challenges that logistics professionals could face in the coming months and years, as the regulatory landscape continues to shift.

Stricter emissions regulations

It’s widely expected that tighter rules governing fleets’ emissions will soon be introduced, with the “zero-emissions” movement gathering steam.

Earlier this year, California enacted the Advanced Clean Fleets rule, which mandates that drayage fleets can only acquire zero-emissions vehicles (ZEVs) going forward. It’s expected that other states could soon follow suit, with New York and New Jersey thought to be among them.

At this point in time, the Trump Administration has not mandated ZEVs across the country – and don’t expect that to change in the near-future. Previous administrations, however, have passed a number of measures to limit the impact of greenhouse gases and other pollutants.

In March 2024, the Environmental Protection Agency (EPA) put the finishing touches to the strongest-yet greenhouse gas pollution standards for medium- and heavy-duty vehicles for model years 2027 through 2032.

Earlier in his tenure, former President Joe Biden also enacted Executive Order 14037, Strengthening American Leadership in Clean Cars and Trucks. Setting out lofty ambitions to “lead the world on clean and efficient cars and trucks,” Biden’s mandate was promptly rolled back by Trump upon returning to office.

In its place, the current president’s administration has ended federal support for electric vehicles and instead prioritized fossil fuels.

While you shouldn’t expect any movement on a federal level, many believe that states will soon take it upon themselves to pass regulation to limit our carbon emissions and it’s essential to be ready for when they do.

Regulation arising from global trade policies

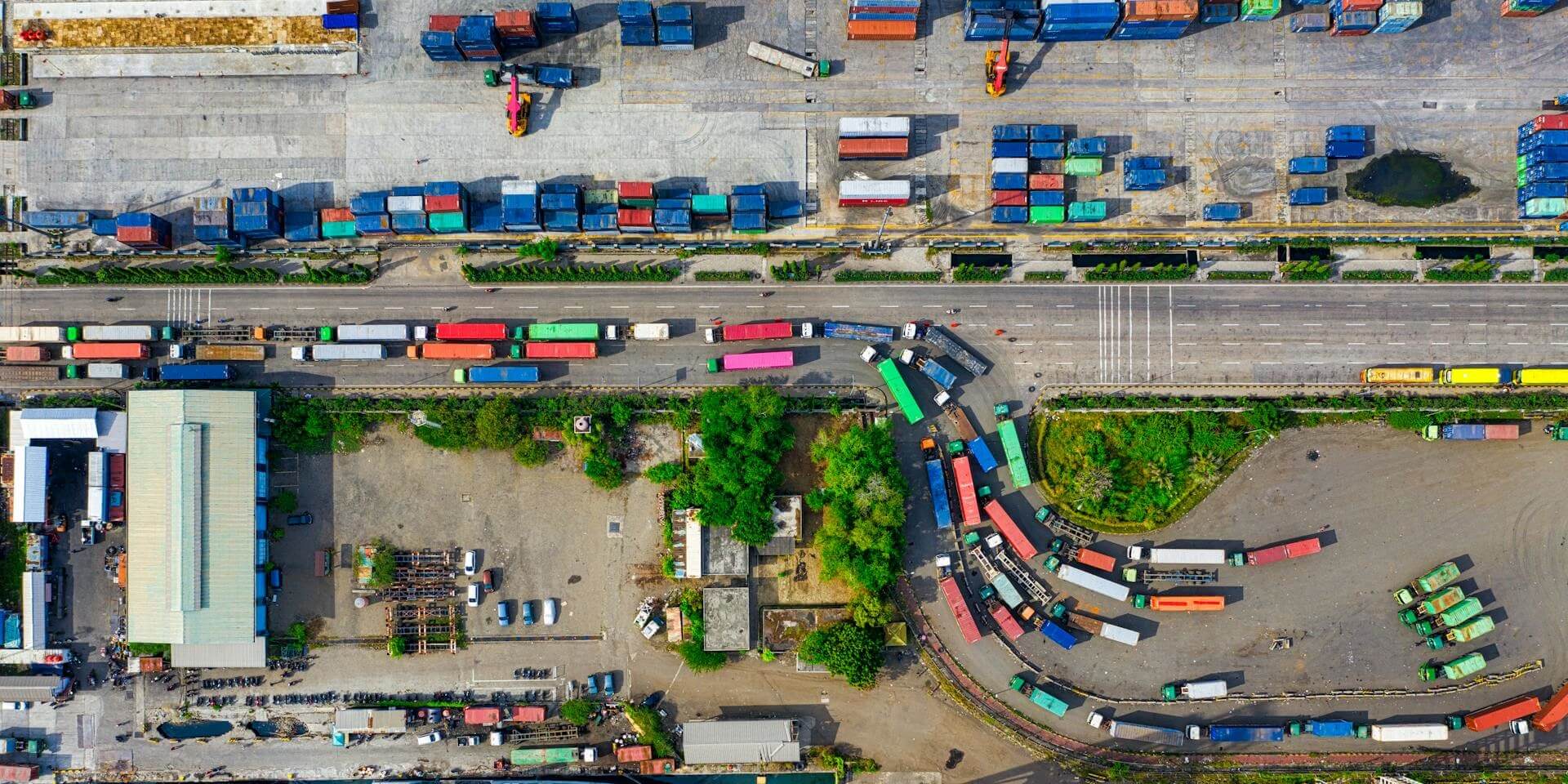

With President Trump’s unprecedented trade war unfolding in real-time, it’s been a tumultuous year in the logistics industry. Many freight businesses have been left scrambling to keep up with the latest tariffs, which are causing backlogs at loading docks, depots, and distribution centers.

The influx of new trade agreements is causing existing routes to become overstretched – and sometimes break down completely. The heavy tariffs on Chinese steel, for example, have led importers to reroute goods through Mexico and countries in Southeast Asia. This has a knock-on effect on ocean traffic, causes chaos at ports, and slows down delivery.

This isn’t sustainable. Logistics businesses, then, face mounting pressure to devise new routes, explore emerging technologies – including drones and self-driving trucks – and ultimately rethink their approach to carrying out their day-to-day business.

How To Stay Ahead of the Latest Regulatory Challenges

Here, I’ll take you through some top tips for getting ahead of the latest compliance hurdles. Follow this guide and you’ll never be forced to play catch-up when the unexpected happens.

Time to invest in tech

…if you haven’t already. As confirmed by 73% of respondents to our latest survey, technology is already helping senior leaders to address workplace challenges. Fleet management software is enabling freight owners to optimize route planning, cut down fuel consumption, reduce idling time, and save big on the bottom line.

Back in the warehouse, technology is helping businesses to automate repetitive tasks, process more orders, and design more efficient workspaces. The benefits that it can bring are massive, with freight firms able to fulfil more orders, scale up, and ultimately boost their revenue.

In recent years, there’s been a real industry focus on improving last-mile delivery. With the COVID pandemic ushering in an ecommerce boom, customers are spending more online — and they want their purchases to arrive faster. According to Forbes, 41% of consumers are even open to paying more to get their packages on the same day, pointing to a growing need for seamless delivery.

In this environment, drones and similar innovations can be really useful, especially in hard-to-reach, rural areas. Zipline, a drone cargo service and partner of Walmart, recently launched in Texas, while Amazon piloted similar deliveries in Europe earlier this year. Expect this space to grow over the coming years.

Audit your processes

It’s also vital that your team conducts regular audits to ensure that your business is in step with the latest compliance. This will be a lengthy process, which encompasses everything from training certifications to proper documentation.

In short, a logistics business comprises many moving parts, and these moving parts need to adhere to government regulations, or everything breaks down.

Your hires should be properly vetted and trained so that they can demonstrate the requisite qualifications for a role in the industry. As an example, the Federal Motor Carrier Safety Administration (FMCSA) recently mandated that all drivers with violations in the Drug and Alcohol Clearinghouse will have their licenses revoked, pending the completion of required return-to-duty procedures.

Elsewhere, the FMCSA plans to soon roll out Department of Transportation (DOT) numbers as the primary identifier for motor carriers. As a fleet manager, it’s your responsibility to eliminate preexisting motor carrier (MC) Numbers from your documentation, as well as to communicate these changes with your clients.

Failure to comply with the shifting sands of regulation will result in fines, business being halted, and much worse.

Make your operations more agile

Regulatory changes have a knock-on effect on how supply chains operate. One of the best ways that your logistics business can insulate itself from these disruptions is by adopting an outcome-driven approach. This will give you the agility to pivot your operations in the face of compliance and market pressures.

For instance, once you’ve identified your desired outcome as sustainability, you can build your overall strategy around this goal. This way, you won’t need to play catch-up when the latest environmental mandate is passed.

An agile business depends upon technology, as well as a lean corporate structure and a culture that encourages proactivity, continuous learning, and willingness to question existing processes. With these pillars in place, your freight firm will be set up to succeed in a challenging regulatory environment.

Fail To Prepare, Prepare To Fail

The logistics industry is at an inflection point. An ongoing labor shortage, coupled with a global trade war, has thrown a lot of people’s plans into disarray. It’s difficult to predict what the next year will look like.

What is more certain is that preparation is the key to staying ahead of the pack. Whether that’s investing in new technology, ensuring your processes are compliant, or introducing an agile business model, a proactive approach will ensure that you don’t get left behind.

To help you keep pace, we’ve put together a report on the biggest challenges and opportunities in the logistics sector in 2025. We spoke to 521 industry experts to get their thoughts on the hiring crisis, tariffs, automation, and more. Use the link below to find out what the industry had to say.