What’s the biggest challenge facing US logistics companies? It’s worker shortages, going by the 63% of respondents in a recent Tech.co report who said their ability to recruit and retain drivers stagnated or worsened in the last year. ATA estimates put the shortage at around 80,000 drivers.

Financial concerns are another key issue, and that’s before logistics companies have fully felt the economic squeeze being brought on, in part, by hefty new tariffs slowing import shipments to the US.

So, how can logistics and transport operations keep their business steady and their reputation intact in 2025, despite headwinds like a lack of qualified drivers or a shrinking budget?

The truth is that there’s no easy answer. Still, here are a few principles to keep in mind while you work towards addressing this incredible challenge.

Manage Expectations Effectively

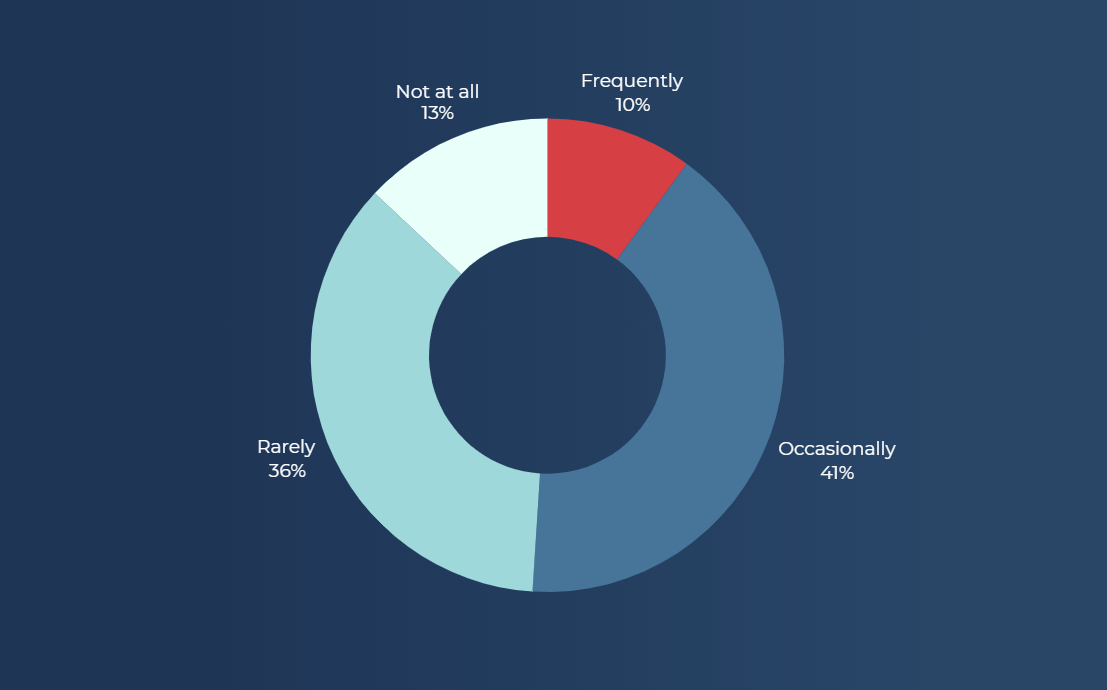

51% of all logistics companies we surveyed told us that driver constraints have occasionally (41%) or frequently (10%) impacted their ability to meet customer expectations. Just 13% are unaffected.

With fewer drivers, you’ll need to reshape your operation in order to best use all your resources while continuing to work past all your restrictions. That starts with open communication and expectation management.

Have driver constraints impacted your ability to meet customer expectations? Source: Tech.co

Practically speaking, your operation can take three big-picture steps to ensure customer expectations are addressed:

Transparency

First, push your internal and your customer-facing culture towards valuing transparancy. Employees should be comfortable delivering bad news to their manager, just as drivers should be comfortable taking their mandated breaks to ensure they don’t risk an hours of service violation.

It’s only by leading with the bad news that you can start to develop a plan to get back on track, and this is true at all levels of any organization.

Communication

One interesting finding from Tech.co’s latest logistics polling: Managers are more likely than owners to see workforce shortages as an urgent issue and to take actions to counter it. Owners are almost twice as likely to say these shortages are a low urgency issue (29% vs. 16%), while 32% of managers say the problem “affects efficiency and planning” compared to 22% of owners.

This indicates an internal communication breakdown. Address this, and you’ll be more likely to see minor operational changes that can help address the issue.

Improved customer service

External communication is also key, and better all-around customer service is even better. By setting up a plan for client communication, you can be ready to spring into action when foreseeable delays or mishaps impact your schedule.

The right CRM software might help you by keeping your customer profiles, social accounts, and email in order, but having a human-staffed customer service team with the right protocols in place will really help. Unless your company is the size of Microsoft, that is, in which case an AI tool might be more cost-effective.

Optimize Operations With Limited Resources

Staying transparent and communicative is great and all, but what steps can you take next? The major theme is “doing less with more.” Logistics companies can’t avoid the resource-sapping challenges ahead, so they’ll need to create new workflows that can maintain revenues.

Do: Adapt new tech

If you operate a fleet, you can save money with the right system. The best fleet management systems can offer better route optimization, which helps managers track traffic or weather changes in real time. By adjusting rapidly to changing conditions, you’ll be able to keep last-mile deliveries or long-haul trips as efficient as possible.

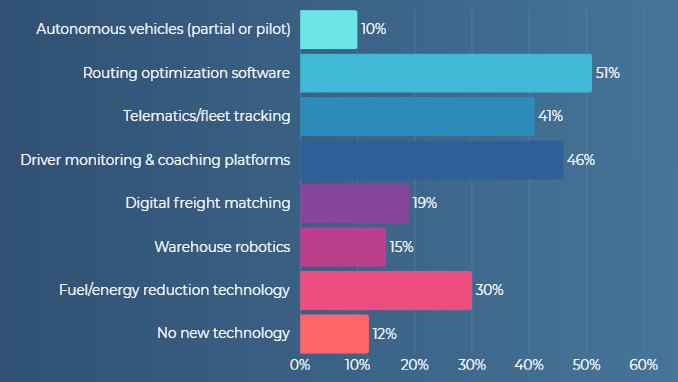

Any form of route optimization software is the most popular tech solution, with 51% of respondents saying they had recently adopted it. Other popular technologies include driver monitoring and safety coaching (46%), telematics tracking (41%), and fuel reduction tech (30%).

What kinds of technologies have you adopted recently? Source: Tech.co

Don’t: Adapt radically new tech

The least popular technologies among logistics companies right now? Warehouse robotics (15%) and autonomous vehicles (10%). These forms of automated processes might be huge time savers once they’re market-ready, but for now, they’re a risky investment that will cost a lot upfront with no proof that they’ll be worth it.

Prioritize core services

Now is not the time to expand into wedding party catering or ice cream trucks. Sit down and think about what elements of your company are not crucial to your business success.

This might mean cutting expenses you can’t justify, or even downgrading to a smaller office when your lease is up. It definitely means you can’t expand the business unless the math works out, and you may need to reduce any business expansion plans you already have in place, such as an upcoming marketing campaign.

Streamline processes

Think about how your business operates currently, and consider how simple tweaks might be able to shorten lead times. Data analytics from telematics-equipped systems might be able to help here, since they can deliver insights that might not be obvious otherwise.

You might be able to better identify customer demand trends, which can help you stock up on the right product before you sell out. Perhaps you’ll spot a preventative vehicle maintenance benefit. Replacing a brake pad early can stop a disruptive collision before it happens.

Invest in the Existing Workforce

Across the next two years, Tech.co research indicates, less than 20% of logistics companies expect the driver shortage to significantly improve, while another 21% expect it to worsen. After all, the average age for a US truck driver is 46 years old, and more than 110,000 of them are over the age of 65.

Keeping your current workforce and adding young drivers starts with company support. This includes basic training, but can also include mentorship programs.

Kruepke Trucking offers one example. Anyone with a training certificate who meets the requirements can join a three-phase mentor program. First, they’ll work with a local trainer for a minimum of one week, followed by working with a trainer over the road for three weeks, and finally working solo in a regional dispatch area for another three weeks. Crucially, candidates are paid throughout the entire process.

PAM Transport offers a mentor program with cash incentives for the mentors themselves, as well. They advertise that mentors can earn up to an additional $25,000 per year. With drivers everywhere often underpaid, support tends to start with a reasonable paycheck. Well-compensated mentors and mentees will be trustworthy and long-lasting.

It’s tough to overstate the importance of the logistics industry: It’s responsible for about 12% of global GDP. You’ll need to invest in your drivers in order to ensure that they help your company stay strong.

Check out our guide to the 18 Best Companies for Employee Benefits and Perks for more inspiration.

Summary: Your Best Asset Is Reputation

As with any business, your company lives and dies on its intangible key asset, reputation.

Reputations won’t disappear in an instant, but they can be eroded over time. Top problem areas in your industry, from labor constraints to thinning budgets, can hurt your reputation slowly at first, before suddenly collapsing it. The only solution is to take steps today that can bolster your image.

In 2025, you’ll need to have a reputation for running a transparent, streamlined logistics company that cares for and supports its workers. If you don’t, you may soon find you aren’t running a logistics company at all.