The biggest reason driving freight operators to adopt new technology is operational efficiency.

A handful of the best software and hardware will pay off in time and money after the initial investment, making it all worth the cost. However, owners often find it tough to push past their cost-conscious instincts and take the plunge.

That’s not ideal in 2026, when tariff rollouts, driver shortages, and general economic instability are posing threats to the already-tight budgets of transportation operations everywhere. The benefits that new technologies can offer are no longer simply nice to have; rather, they are critical for survival and growth.

Here are the core challenges that technology can address within the logistics and freight industry, and why you need to invest in tech solutions today if you plan to thrive tomorrow.

Addressing Workforce Shortages & Labor Costs

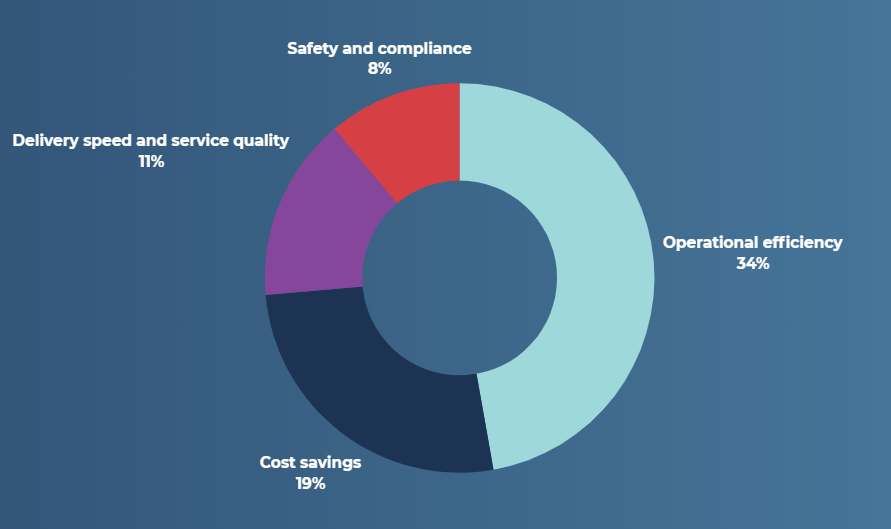

“Operational efficiency” was the top motivator for those buying new logistics technology, cited by an entire third (34%) of respondents to the Tech.co Logistics Report 2025, which collects insights from more than five hundred logistics owners, managers, and others. You can download the full report here.

If you’re just looking for the highlights, however: 25% of US freight firms say a labor shortage is the biggest issue affecting their business. The sector could be missing as many as 160,000 driver positions by 2030. Other areas of concern include rising diesel prices, cited by 23%, and the “major unforeseen disruptions”, which were brought up by 16% of the businesses we spoke to.

Naturally, recruitment and retention are top priorities, although this means labor costs are expected to increase along with the rising costs of keeping fuel tanks topped off.

This guide will take a look at all the tech-related factors that logistics companies need to keep an eye on in order to maintain their focus on core needs like retention, and well as cover some of the actions businesses should take to prepare for autonomous vehicles.

Enhancing Productivity

Operational efficiency may be the top reason why logistics operators are turning to new tech solutions, but it’s not the only one. Cost savings were the second most common reason cited, with nearly one in five (19%) highlighting this as a motivating factor behind their decision to invest in technology.

In other words, the biggest reason to invest in tech is to “do more,” and the second biggest reason is “with less.” Enhancing productivity allows people to do more with less.

What is your motivator for adopting logistics tech? Source: Tech.co survey results

If a transport company isn’t keeping up, they’ll miss deliveries and could even break supply chains. Eventually, their reputation can take a hit, establishing a vicious cycle that’s hard to break.

Boosting staff efficiency is a key way to save time and money at any operation, not just logistics. If your company has been steadily growing for years, a simple audit can likely find plenty of processes that can be streamlined or reduced to free up more work hours.

Why non-adoption is risky

Rising costs and the continued driver shortage are shrinking capabilities at logistics companies everywhere. 63% of Tech.co Logistics Report 2025 respondents stated their ability to recruit and retain drivers had taken a hit in the last year. Increasing productivity by just a few percentage points can balance out those losses, keeping companies in the black.

Technology to consider

Fleet management systems (FMSs) are the top tech solution for overall efficiency. These systems gather real-time data on every vehicle’s location, speed, and engine status, allowing managers to rapidly adjust to challenges like unpredictable traffic and weather, as well as automatically calculating the best fuel- and time-saving routes to take when scheduling deliveries across multiple locations in a single day.

Improving Customer Experience & Satisfaction

Tech.co’s new report found that 9 in 10 respondents (91%) agree with the statement that America’s economy depends on fast, affordable, reliable freight movement.

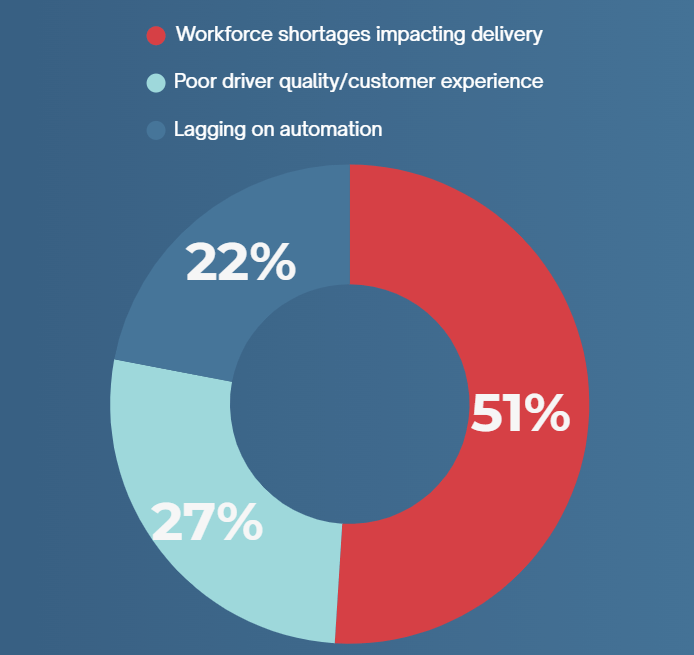

The challenge might be getting customers to agree. Meeting customer expectations can be tough when they’re used to fast-fashion styles and two-day delivery times. Poor customer experiences and driver quality can cause major damage to company reputations, with 27% of respondents saying they were actively concerned about it.

What is the biggest long-term reputational risk for your logistics company? Source: Tech.co survey results

Granted, that’s far below the top issue of driver workforce shortages, which 51% noted, but it’s still a big deal. Any businesses that rely on meeting the needs of a client or customer base must have a support team to troubleshoot problems as they arise, as well as a smart team that can work to stop problems before they arise at all.

Why non-adoption is risky

Company reputations are fickle things: They seem rock-solid right up until they crumble completely. By the time you realize that you need to save your reputation, it’s likely already too late. Don’t look at your customer happiness scores.

Instead, look at your historical record of on-time deliveries or individual complaints and how they’ve been handled. If either one is increasing, you might be in trouble. And, if you’re using the most up-to-date technology available to track these kinds of metrics, you’ll be much more likely to spot problems (and deal with them) earlier.

Technology to consider

A good client relationship management (CRM) software will help you keep your customers happy. Not every business model needs one – perhaps your company has a small amount of long-term contracts to fulfil that won’t require a huge trove of client profiles.

But if you manage a raft of clients, a CRM will keep all your customer communication details in one spot, thanks to tools including unified inboxes, team calendars, and task management.

Boosting Safety

Driver safety is a top concern for logistics companies, and it’s one that technology is uniquely positioned to address.

Hardware units within a vehicle can immediately register a collision when it occurs, giving managers the ability to respond within just minutes after a catastrophe. They can also flag less serious safety issues, such as speeding, which can give managers historical data that can guide them when discussing each driver’s personal safety record.

In fact, 10% of managers cited “driver safety and compliance” as the main reason they started using new logistics technology, with 7% of managers saying the same.

Why non-adoption is risky

The potential financial losses are clear, but a lack of safety measures can also stem future growth, since it can discourage potential drivers from coming onboard a company. 16% of respondents said that safety concerns served as the primary barrier in attracting new drivers to their workforce.

Technology to consider

Once again, a good fleet management system can solve these problems. Many of the top options, from Samsara to Verizon Connect, come with safety programs that will track each driver’s history with speeding, HOS violations, and even harsh braking incidents. Managers can use this data to address problem areas before they turn into major collisions.

Additionally, adopting predictive maintenance is a great way to boost the health and safety of your fleet operators. This model of maintenance relies upon asset tracking and data analysis to provide up-to-the-minute vehicle and asset diagnostics, meaning that you can schedule maintenance before it becomes a matter of urgency.

Improving Sustainability

Clean energy sources like solar and electric are growing by leaps and bounds.

Other emerging technologies in various fields are likely too numerous to mention, but Pulpatronics is one good starting point: The startup has developed RFID tags that are biodegradable, potentially saving landfills from the 30 billion single-use tags that are dumped annually. Keep an eye out in your industry for new types of sustainable tech that can save your budget.

Some businesses can even build business models off of sustainable practices. Take Woodchuck as one example: The wood processing startup saves waste haulers from paying disposal fees by buying their waste. Not only has it diverted over 60% of incoming wood waste from landfills, but it can then often sell the wood to manufacturing facilities that use it as clean fuel, without the need for additional processing.

Why non-adoption is risky

Finding green energy sources and sustainable assets is future-proofing: Increased regulations will likely emerge down the road to encourage better energy conservation, and the businesses with the most sustainable workflows will weather the storm the easiest.

Technology to Consider

For transportation, upgrading to a hybrid or electric vehicle is the most obvious move, with the added benefit of fuel savings. If your company balks at the hefty initial investment for a brand-new fleet, you might instead look towards relatively smaller investments, like installing solar panels on your properties or switching to biodegradable RFIDs.

Data-Driven Decisions and Regulatory Compliance

Truckers must track their hours of service, taking federally manadated breaks at the right time. Tracking fuel use across state lines can come it handy as well, since it allows managers to get the right tax breaks with IFTA reports.

More regulations are on the way, too, even with the particularly light regulatory hand of the current administration. In fact, there are new trucking regulations released every year, while older rules are often modified. In 2026, for instance, Class 3 to 6 heavy trucks now need to add Automatic Emergency Braking systems, the Crash Preventability Determination Program (CPDP) will be expanding, and the ELD mandate see some changes.

The right reports can uncover data insights that can take your company beyond just compliance, too: Some cameras can help managers track and analyze drivers’ cell phone events or even instances of drowsiness.

Why non-adoption is risky

Fail a roadside inspection? Your vehicle will be placed out of service for long enough to put a dent in your company’s quarterly profits. These clear-cut cases of lost revenue aren’t the only risk, either. Without data analysis on fleet performance, you might miss hidden insights that could help you gain an edge over the competition by making small but meaningful changes.

Technology to Consider

Once again, fleet management systems are the best bet for data collection and compliance. There’s a reason we’ve mentioned them two other times in this guide: They’re a one-stop-shop for fleet needs.

If a full FMS with all the bells and whistles is too pricy for a tiny fleet, consider the stripped-down alternative, the ELD device. These systems handle all the legal compliance that a US fleet needs to track, and they’re the bare minimum for operations hoping to avoid an audit from their friends at the Federal Motor Carrier Safety Administration.

Next Steps: Review Top Brands for Your Needs

Today, a mere 3% of logistics service providers say they have no digital transformation strategy. But figuring out a specific strategy that saves money with a low upfront investment is easier said than done.

We recommend starting with a top fleet management system by checking out our guide to the best brands and their costs. An FMS will help with more efficient routing, better safety tracking, and all the compliance and report technology your data-hungry hearts desire.

Other popular options include the best CRM software or the best ELD devices. Whatever you settle on, rest assured: You have all the time-saving, easily-integrated tech tools you need to keep a logistics operation sustainable into 2026 and beyond.